For the purposes of getting a handle on the intricacies of diamond cutting I would like to concentrate initially on ‘The Round Brilliant Cut’. Please keep in mind though that similar rules or factors are considered very closely when cutting any shape of diamond from the rough crystal. Maximum weight, maximum Brilliance, maximum value.

While nature determines a diamond’s clarity, carat weight, and color. The hand of a master cutter known as the ‘Brillianteer’ is necessary to release its fire, sparkle, and beauty. A well cut or faceted diamond, regardless of its shape, scintillates with fire and light, offering the greatest brilliance and value.

When a diamond is cut to perfect proportions, a phenomenon called Total Internal Reflection can be achieved. This happens when the light entering the Diamond through the Table and upper facets is reflected internally from one mirror-like facet to another and is then dispersed back through the top of the stone. The result is a display of maximum brilliance and fire.

Diamonds cut too deep or too shallow lose light that spills through the side or bottom. As a result, poorly cut stones will be less brilliant and beautiful and certainly less valuable.

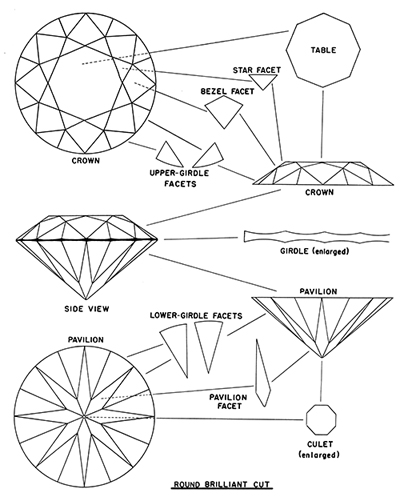

Understanding Facet Names

The modern round brilliant consists of 58 facets (or 57 if the culet is excluded); 33 on the crown (the top half above the middle or girdle of the stone) and 25 on the pavilion (the lower half below the girdle). In recent decades, most girdles are faceted. Many girdles have 32, 64, 80, or 96 facets; these facets are not counted in the total. While the facet count is standard, the actual proportions (crown height and angle, pavilion depth, etc.) are not universally agreed upon.

Diamond cutting and polishing

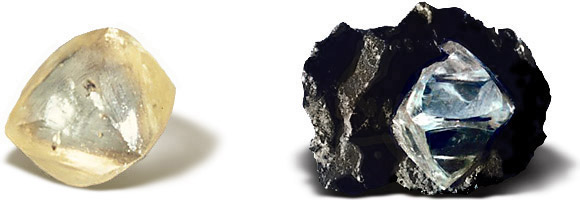

In its rough form, a diamond is a lackluster, translucent crystal. Transforming a rough diamond into a sparkling jewel requires several procedures: marking, cleaving, sawing, bruting, cross working and brillianteering.

Marking

The “marker” studies and then marks the rough to direct the removal of inclusions, and indicate how the piece should be cleaved or sawn. For large, extremely valuable pieces, this stage may take weeks or months.

Cleaving

Cleaving involves the removal of impurities or irregularities in the rough diamond. Using a second diamond or a laser, a groove is carved into the diamond along a plane of weakness. A steel blade is placed in the groove and a sharp blow is delivered which splits the stone. Cleaving requires particular skill; if pressure is applied to the wrong area or in the wrong direction, the diamond may shatter. Not all rough diamonds require cleaving or sawing – some diamond rough is well formed and is in ready-to-cut form.

Bruting

The diamond is placed in a lathe with another diamond that is rubbed against it to create the rough finish of the girdle.

Sawing

Diamond sawing is a twentieth century innovation. Although cleaving may be efficient, it limits the cutter to shaping the stone according to its natural lines of cleavage. Sometimes, diamonds have to be cut against a cleavage plane (against the grain). The diamond saw, a lubricated circular steel blade allows cutters to go against the grain of the diamond without shattering it.

Moreover, the diamond saw allows diamonds to be salvaged from misshaped diamond rough. Sawing is a more expensive process than cleaving, as it requires about one-tenth of a carat of diamond dust (applied to the saw with oil) for every carat of sawed diamond. It is also a much slower process than the single-stroke process of cleaving. It may take days to saw through a two-carat diamond. Some current methods include the use of lasers to saw through diamonds.

Polishing

Diamond consists of two phases, crossworking and brillianteering. To give the diamond its finished look, it is clamped to on an armature above a rotating polishing wheel (scaif). Diamond dust on the wheel’s surface grinds the diamond down to the desired angle. The scaif makes it possible to symmetrically polish all the facets of the diamond at angles that reflect the most light.

Cross Working

Cross-workers carefully evaluate the clarity of the finished diamond in relation to its final size in order to obtain the maximum value for the finished stone. The work is performed on a spinning polishing disc covered with diamond powder. The diamond is held in a clamp and the facets are created one at at time. Crossworkers polish 18 facets to stringent measurements and angles.

Brillianteering

The function of brillianteers is to create and polish the additional 40 facets to produce a brilliant cut diamond with 58 facets.